Punch plate flowmeter

During the production, processing, storage and transportation of various bulk materials such as grain, building materials, metallurgy, salt and chemical raw materials, real-time measurement of material flow has become an increasingly necessary means in modern management and optimization of process flow. Especially in realizing material ratio and seal control, DLD series flush plate flow smothering meter is your ideal detection and control instrument. The instrument is more and more widely used because of its good accuracy, extremely low failure rate and low price. It will soon replace traditional instruments in the same application field. The instrument is especially suitable for real-time detection of pipeline flow. During the development, application and improvement of DLD series flowmeters in recent years, the characteristics of similar products at home and abroad, such as "SANKYO" in Japan and "Endress+Hauser" in Germany, have been distinguished successively. Through learning from each other and continuous practice, the instrument has been placed at the priority level of similar products in terms of structure and performance.

Product Details

Structural Composition:

1、 Weighing Instrument

1. Comprehensive error of instrument:<0.02%

2. Sensor input port: 6 350 ohm sensors can be connected, and the sensor sensitivity is required to be above 1.5mv/v.

3. Weighing instrument: 32 bit ARM CPU is used for high reliability and fast operation.

4. Wide power supply design: 85V-260V 50HZ

5. 24 bit ADC sampling module, speed 240 times/second. Chinese and English menu display, 6 channels of switching value, 2 channels of analog input and 2 channels of analog output. Large LCD display. The standard RS485 interface (modbus protocol) can fully connect with the DC S.

2、 Load Cell

The weighing sensor with high sensitivity above 2mv and temperature compensation function shall be used to adapt to the environment of - 30 ° C - 60 ° C

No drift, stable operation, high accuracy.

3、 Performance Benefits

The instrument is designed according to the principle of impact weight and kinetic energy. When the bulk material passes through the "rectifier" or directly acts on the punching plate, the material will be forced to change the flow direction and flow speed, and the result will produce a force on the heavy flow detection mechanism. By detecting the force, the current weight of the material can be converted. After the signal of the sensor in the primary instrument is transformed, it is transmitted to the secondary instrument through the signal line. The secondary instrument uses a 24 bit microcomputer controller. By receiving the signal of the primary instrument, the instantaneous flow weight and the cumulative flow weight are calculated. At the same time, the feeding speed of the feeding equipment can be automatically adjusted according to the set flow seal value.

Punch plate flowmeter - main technical features and functions

◆ Even if there are many material residues on the punching plate, there is no zero drift.

◆ It can measure granular materials, powder materials, powder particle mixtures, small block materials, high viscosity materials and high-temperature materials.

◆ The secondary instrument (microcomputer controller) can be placed together with the primary instrument or remotely to facilitate the centralized display and management of multiple instruments.

◆ The secondary instrument adopts a 16 bit microcomputer controller with standard input, output interfaces and DcS interfaces, which is easy to realize the networked management of the factory. Sufficient function expansion reservation can meet different specific requirements of different users in production and management.

◆ Online flow setting and modification are convenient for users to adjust the process.

◆ It can be used in conjunction with various feeding mechanisms such as conveyor belt, winch cage, vibration discharger, impeller, bucket elevator, door hopper, etc. to realize automatic P regulation of material flow and material ratio.

◆ High reliability and minimum maintenance, simple structure, few friction parts and few failures.

◆ Real time continuous measurement of material flow, with good dynamic characteristics.

◆ The primary instrument can be placed in any environment except the liquid, with double height sealing.

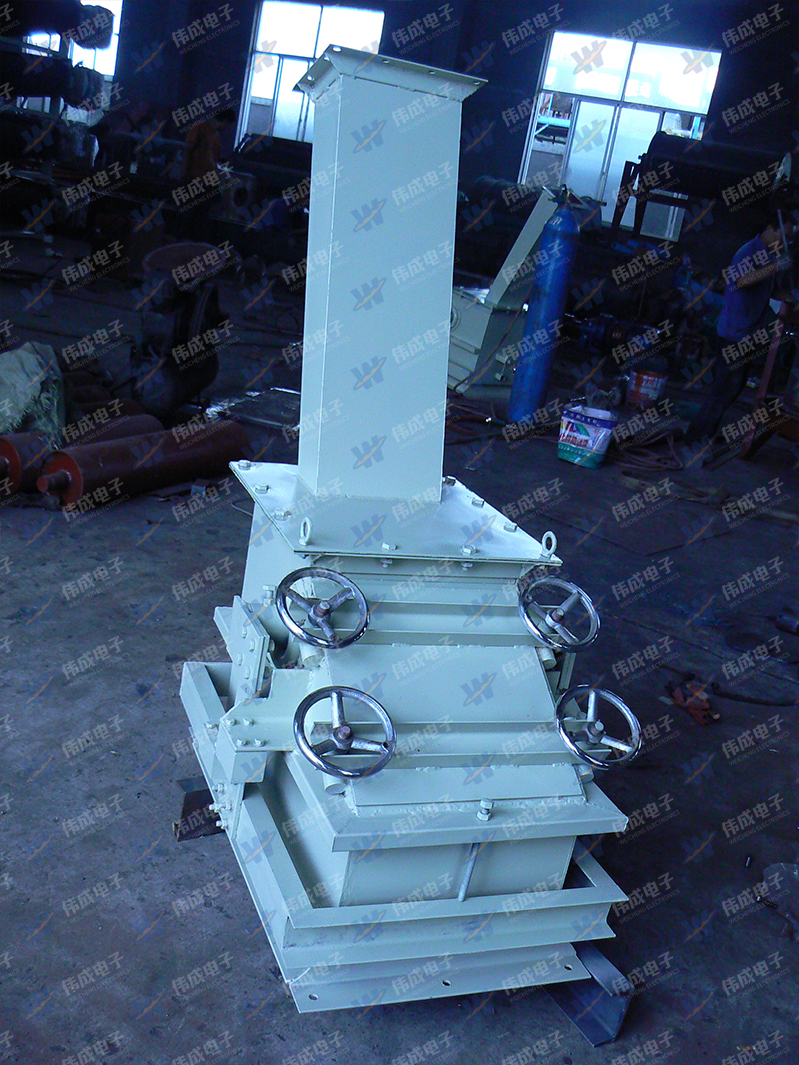

Product Live Shot:

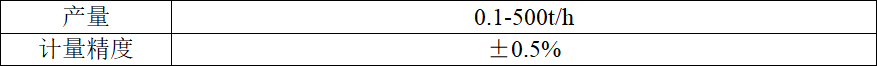

Technical parameters: (customized as required)

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code