Screw scale for metering under speed increase

WC-TJ speed regulating metering screw scale: it is a production metering equipment that can continuously transport, dynamically measure and control the feeding of various powdery and granular materials. It is widely used in cement, chemical industry, metallurgy, ceramics, grain, transportation and other industries. As a complete machine automation device for metering and batching, it can provide accurate metering data and control means for on-site management and operation. Equipped with standard RS485 communication interface, the modbus RTU/profibus DP communication protocol is implemented, which can easily communicate with the configuration software without the need to customize special drivers.

Product Details

Structural Composition:

1、 Weighing Instrument

1. Comprehensive error of instrument:<0.02%

2. Sensor input port: 6 350 ohm sensors can be connected, and the sensor sensitivity is required to be above 1.5mv/v.

3. Weighing instrument: 32 bit ARM CPU is used for high reliability and fast operation.

4. Wide power supply design: 85V-260V 50HZ

5. 24 bit ADC sampling module, speed 240 times/second. Chinese and English menu display, 6 channels of switching value, 2 channels of analog input and 2 channels of analog output. Large LCD display. The standard RS485 interface (modbus protocol) can fully connect with the DC S.

2、 Load cell

The weighing sensor with high sensitivity of more than 2mv and temperature compensation function shall be used to adapt to the environment of - 30 ° C - 60 ° C.

No drift, stable operation, high accuracy

3、 Excellent Frequency Converter

It adopts foreign or domestic first-line brands, high-performance vector control technology, with wide speed regulation range, accurate speed regulation and strong overload capacity, fully meeting the demand for quantitative batching control

4、

Accurate processing shall be adopted, the distance between coaxial blade and cylinder wall shall be less than 3mm, seamless steel pipe or U-shaped structure shall be adopted, and double seals such as tetrafluoroethylene and packing shall be adopted for sealing, with good sealing effect. The steady flow spiral adopts the methods of variable diameter, variable pitch or overflow, with uniform discharge and good material locking effect. Especially for materials with poor fluidity, the discharge is smooth and stable by increasing the size of the feed inlet (using double tube spiral or star discharger for feeding). Single pipe or spiral batching system can be freely selected according to different processes on site. For high temperature places, measures such as adding water circulation cooling system and equipping high temperature resistant sensors are taken to solve the problem.

Product Live Shot:

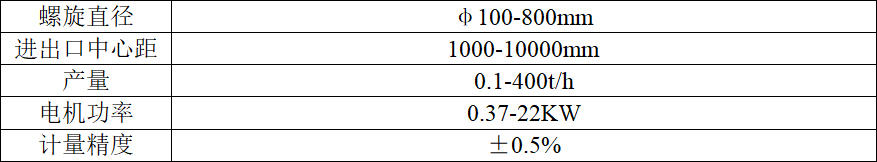

Technical Parameters: (Vustomized As Required)

Project Case:

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code