NJGC pressure resistant weighing coal feeder

Pressure resistant belt weighing coal feeder is an energy-saving and environment-friendly coal feeder designed for circulating fluidized bed coal-fired boiler systems in power generation, chemical industry, metallurgy and other industries. With continuous coal feeding, dynamic measurement and high accuracy, it can effectively improve the boiler performance, conduct temperature detection, control hot air return, make the system operate more stably, provide accurate and reliable measurement data and control means for on-site management and operation, and is an advanced coal metering and feeding equipment that meets the requirements of boiler technology.

Product Details

Structural composition:

1、 Weighing instrument

1. Comprehensive error of instrument:<0.02%

2. Sensor input port: 6 350 ohm sensors can be connected, and the sensor sensitivity is required to be above 1.5mv/v.

3. Weighing instrument: 32 bit ARM CPU is used for high reliability and fast operation.

4. Wide power supply design: 85V-260V 50HZ

5. 24 bit ADC sampling module, speed 240 times/second. Chinese and English menu display, 6 channels of switching value, 2 channels of analog input and 2 channels of analog output. Large LCD display. The standard RS485 interface (modbus protocol) can fully connect with the DC S.

2、 Speed sensor or encoder

1. The pulse shaping circuit is added to the speed measuring input of the speed measuring sensor, which can make the speed measuring result more accurate and stable.

2. 8030-1024 photoelectric encoder φ The roller at the end of the axle hole is directly connected, with good concentricity and long service life. Strong anti-interference ability.

3、 Load cell

The weighing sensor with high sensitivity above 2mv and temperature compensation function shall be used to adapt to the environment of - 30 ° C - 60 ° C

No drift, stable operation, high accuracy.

4、 Excellent frequency converter

It adopts foreign or domestic first-line brands, high-performance vector control technology, with wide speed range, accurate speed regulation and strong overload capacity, fully meeting the demand for quantitative batching control.

5、 Cleaning device

The chain scraper cleaning device can automatically clean the dust in the machine.

6、 Totally enclosed housing

1. The 6-8mm steel plate is processed into a full closed barrel structure, so that the dust does not rise. It has a unique anti deviation technology, and the pressure is 0.35MP.

2. Direct operation through the side access window of the coal feeder is convenient for maintenance and belt replacement, reducing the maintenance space;

3. The combined weighing and conveying components can be drawn out from the housing for easy maintenance and overhaul (optional);

4. Variable frequency stepless speed regulation, stable operation, can meet the requirements of on-site open loop or closed loop regulation of different flows;

5. Flexible skirt polyester canvas conveyor belt is adopted to ensure no material scattering and minimum expansion rate;

6. Quick shut-off device, electric or pneumatic high-temperature isolation valve, to prevent hot air backflow, high safety;

7. Perfect alarm system, timely find and remove coal blockage, coal break, belt deviation and other faults;

8. It can be interlocked with system equipment to realize intelligent control.

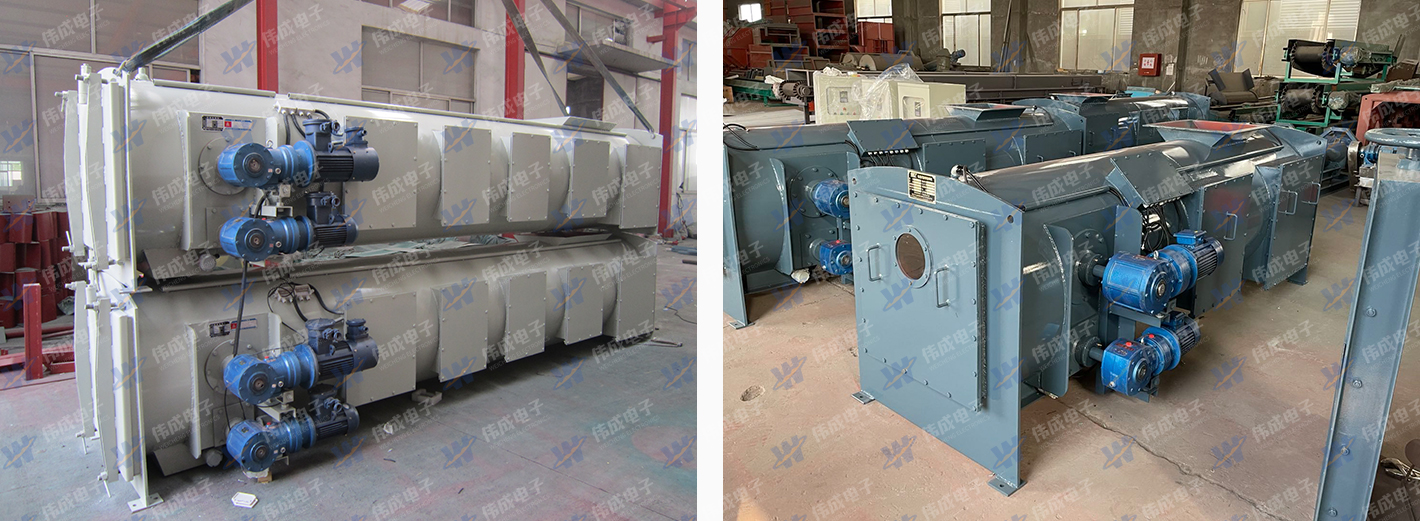

Product live shot:

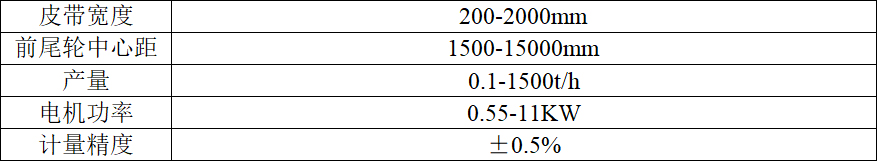

Technical parameters: (customized as required)

Use pictures:

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code