Original Schenck instrument

LX-163 is an intelligent control instrument specially developed by our company to realize the batching, metering and control of bulk materials.

LX-163 can form a control system with PLC through analog and switch input/output interfaces, and can form a DCS system with remote host through field bus. It can be used for liver quantitative feeding control and batch feeding control.

Product Details

1.1 Reasons for choosing LX-163:

Strong anti-interference ability-

The operation is simpler and more intelligent.

1.2 Technical characteristics of LX-163 control instrument

The motherboard adopts ARM 32-bit CPU, which has fast operation speed, good electromagnetic compatibility and strong anti radiation interference capability;

CPU and port adopt omnidirectional isolation, with strong anti-static and conductive interference capability;

The layout and opening size of the instrument port are downward compatible, facilitating instrument replacement and upgrading

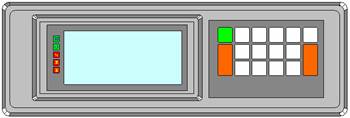

Large dot matrix LCD display technology, 19264 dot matrix;

Soft touch film keyboard, large key area, comfortable feel;

A more perfect communication protocol can realize remote calibration with computer software, which is independent of conventional keyboard operation;

1.3 Technical indexes of LX-163 control instrument

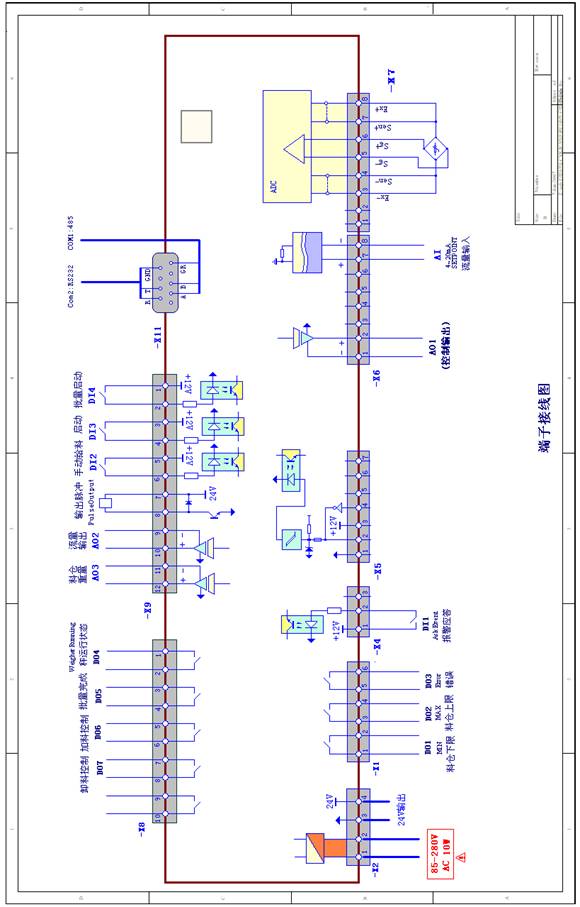

1.3.1 Power supply

LX-163 control instrument power supply is AC 85-265V, and the maximum consumption power is 10W.

1.3.2 Appearance characteristics

·Aluminum alloy box shell, good sealing, dust resistance, more suitable for industrial applications.

·Standard disc installation, opening size: wide × Height=275mnm × 86mn (the overall dimension of the instrument is wide × high × Depth=288 × 98mm × 185mm)

1.3.3 Input interface

·One way weighing module: power supply: 10V/100mA, input range: 0-25mV;

Note: Please use standard resistance strain gauge load cell.

Five programmable switch input; it can be used for starting operation, batch operation input, alarm reset and manual feeding. The analog input port is programmable, and the ports used for each input are set through parameters BO6 and Q01-04. The setting of "startup input" can be switched directly by pressing [3 in the function menu. The input port is defined as:

DI1=alarm reset DI2=manual feeding DI3=start DI4=start batch

Note: Please connect passive contacts externally.

One analog input (flow setting input);

4-20mA input.

1.3.4 Output interface

·Three programmable 4-20mA analog output: 0-500 Ω; set by EO1/E04/EO7.

·Two way digital field bus: one is RS-485 standard communication interface, and the other is RS-232 standard communication interface;

Seven programmable switching value (relay). Output relay nominal: 5A@250VAC 。 The on-off output can be used for fault alarm, feeding control, unloading control, upper limit of flow, lower limit of flow, lower limit of warehouse weight, upper limit of warehouse weight, batch operation, control over deviation, operation status and batch completion. It can be defined during switching value output, and the ports used by each output function can be set through parameter R01-R17. The factory output port is defined as follows:

D01=lower limit of warehouse weight DO2=upper limit of warehouse weight DO3=fault alarm DO4=operation status DO5=batch completion DO6=feeding start DO7=unloading start

·One channel pulse counting output (Max: 10Hz).

Note: Pulse output is fixed for remote cumulative display.

1.3.5 Environmental adaptability

·The operating temperature range of LX-163 control instrument is - 20 ℃~55 ℃, and the humidity is 10%~95% non condensing.

·LX-163 control instrument is not an intrinsically safe instrument. Please connect an appropriate fuse when using it.

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code