Fully sealed quantitative feeder

Fully sealed constant weight feeder: models include WC-DEM, WC-DEL, WC-TDGSK, WC-TDG, etc. It is a high-tech product integrating transportation, weighing and quantitative control. It can adapt to various production environments. It can continuously mix, measure and batch mix various block and granular materials (such as limestone, iron powder, clay, coal, grain, fertilizer) and granular materials (such as fly ash, cement. Powder materials are sealed), Provide accurate measurement data and save data for production control and management of various industrial sites. It can be used in cement, building materials, metallurgy, chemical industry, glass, ceramics, fertilizer, grain, medicine and other industries. Equipped with standard RS485 communication interface, the modbus RTU/profibus DP communication protocol is implemented, which can easily communicate with the configuration software without the need to customize special drivers.

Product Details

Structural composition:

1、 Weighing instrument

1. Comprehensive error of instrument:<0.02%

2. Sensor input port: 6 350 ohm sensors can be connected, and the sensor sensitivity is required to be above 1.5mv/v.

3. Weighing instrument: 32 bit ARM CPU is used for high reliability and fast operation.

4. Wide power supply design: 85V-260V 50HZ

5. 24 bit ADC sampling module, speed 240 times/second. Chinese and English menu display, 6 channels of switching value, 2 channels of analog input and 2 channels of analog output. Large LCD display. The standard RS485 interface (modbus protocol) can fully connect with DCS.

2、 Speed sensor or encoder

1. The pulse shaping circuit is added to the speed measuring input of the speed measuring sensor, which can make the speed measuring result more accurate and stable.

2. 8030-1024 photoelectric encoder φ The roller at the end of the axle hole is directly connected, with good concentricity and long service life. Strong anti-interference ability.

3、 Load cell

The weighing sensor with high sensitivity of more than 2mv and temperature compensation function shall be used to adapt to the environment of - 30 ° C - 60 ° C. No drift, stable operation, high accuracy.四、优异变频器

采用国外或国内一线品牌,高性能矢量控制技术,具有调速范围宽、调速准确和强过载能力,充分满足定量配料控制需求。

Scale body characteristics

1. Scale frame:

The scale body is made of 5mm cold-rolled plates, which are bent into a C-shaped frame structure at one time. It has high strength, stable structure and is not easy to deform.

2. Drive:

The transmission device (motor reducer) adopts SEW or SBD Schenck scale special reducer, which is installed in the shaft hole suspension direct connection mode, and the belt is driven directly by the driving roller (without vibration and smooth movement).

3. Guide and automatic deviation correction device:

During the belt operation, when the belt deviates to one side due to an external force, the deviation correction device of the scale body will automatically push the counterweight device through the connecting rod to force the belt to reset automatically by using the reverse force.

4. Automatic tension adjusting device:

调整从动辊张紧螺旋可调节秤体皮带的张紧度,保持输送皮带的张力恒定,并通过导向挡滚和自动纠偏装置防止皮带跑偏、打滑。

5. The driving roll and driven roll of the scale body adopt a unique waist drum structure to effectively prevent belt deviation. The driving roll and driven roll are coated with glue to effectively prevent the belt from slipping.

6. All bearings of the belt weigher are imported bearings, which are waterproof, firmly sealed and durable. Fully adapt to harsh environment and have a long service life.

7. The feed inlet is equipped with a material flow shaping ram to facilitate the adjustment of the material layer thickness.

8. There are pear shaped cleaners and rubber scrapers between the belt and the roller, which can clear the adhesive materials on the belt at any time to ensure the measurement accuracy and zero point stability of the scale body.

9. Both sides of the scale body are equipped with (emergency stop) switch devices to connect with the controller, which can realize on-site power-off and shutdown, and make maintenance safe and more convenient.

10. It has the automatic cleaning function of reducer motor and scraper chain plate, effectively overcoming the problem of material accumulation.

Product live shot:

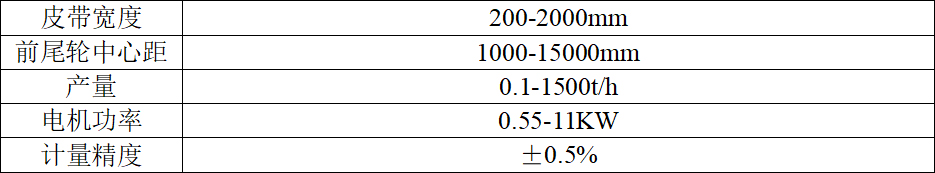

Technical parameters: (customized as required)

Project case:

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code