Plough discharger

The product is widely used for sectional unloading of conveyors in mines, metallurgy, electric fields, coal yards, gathering stations, ports and docks. The hydraulic plough type discharger is a mechanical product installed on the middle frame of the belt conveyor to perform unloading and control the flow and direction of material transportation, and can uniformly and continuously unload the materials conveyed into the hopper or required places. The discharger adds variable slot angle, auxiliary plough, etc., and uses electro-hydraulic push rod as the power source to overcome the shortcomings of the old discharger, such as endless plow materials, poor tape scraping and overload capacity, often burning the motor, top bending lead screw, and easy mechanical damage.

Product Details

working principle

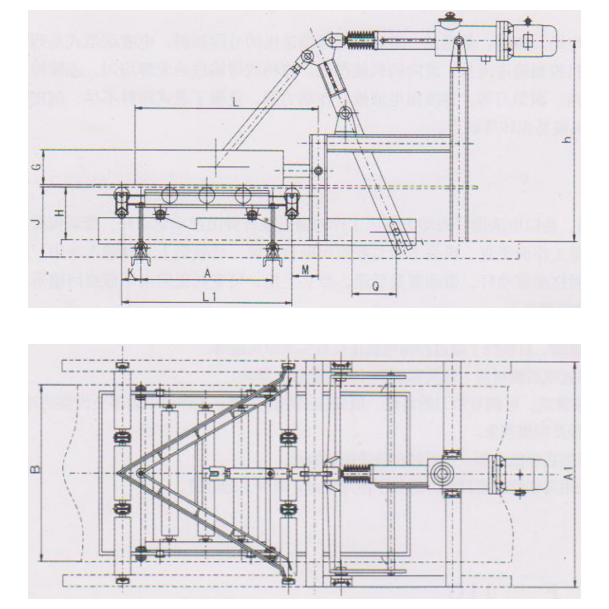

DYNT type single and double side wear-resistant plough discharger uses the electro-hydraulic push rod as the power source. When working, it extends the drive rod through the push rod, drives the frame forward to complete the head fall, and supports the flat underpinning group to make the tape working surface straight, the lower edge of the head closely fits the tape surface, writes the materials on the tape into the bucket, and sends them to the required place. After unloading, it starts the electro-hydraulic push rod to retract the drive rod, drives the frame backward, and the plow head is lifted up, The variable underpinning mixing group changes from parallel to groove shape, allowing materials to pass through smoothly. (See the push rod part for the action principle of the electrohydraulic push rod)

working principle:

1. The power source drive part is the latest manual and electric dual-purpose hydraulic electro-hydraulic push rod in China, which overcomes the defects of the electric push rod (poor overload capacity, burning motor, lead screw top bending) and gets stuck, maintains the advantages of the electric push rod (no leakage, self reliant), and realizes the lifting and falling of the plow by controlling the positive and negative rotation of the motor.

2. The plow head is divided into the front part (alloy chrome manganese or asbestos material) and the rear part (wear-resistant rubber plate).

3. The cable tightening device added to the plow head is a mechanical tension type, which can adjust the height of the plow blade. The height of the plow blade can be adjusted to stick the tape with the best surface. The plow blade will not lift or shake due to the impact of coal during operation, thus avoiding the tearing, wear and coal leakage of the tape.

4. According to the user's requirements, the electro-hydraulic push rod can be installed on the upper part of the coal machine or on both sides of the belt.

5. The flap of the special air lock funnel of the discharger is made of high chrome manganese wear-resistant material, which extends the service life and reduces the maintenance.

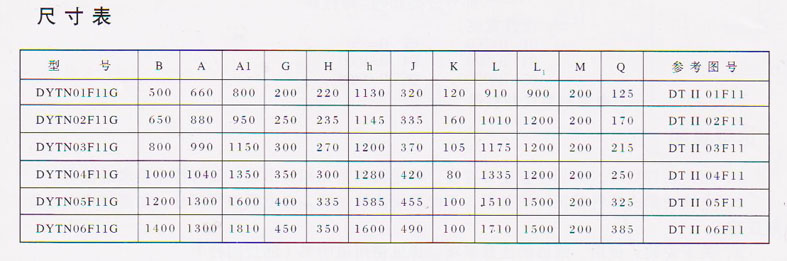

Model description

DYTN: electro-hydraulic plough discharger

01: Belt width:

01B: 500

02B:650

03B: 800

04B:1000

05B: 1200

06B: 1400

F: Part of classification code: discharger

11G: 11G bilateral, 12G right, 13G left

Model Selection Description

1. When ordering, the user must pay attention to the belt width and the unloading form of the conveyor trough angle. If there are special requirements, please explain them.

2. Under normal conditions, electrohydraulic plow dischargers are not equipped with buffer air lock funnels and electrical control parts. Please indicate when ordering if necessary.

3. Please refer to the User Manual for the installation, use and maintenance precautions.

Basic formula

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code