High angle belt conveyor

This series of products are mainly used for continuous conveying of bulk materials at large inclination angles, using conveyor belts with wavy edges and diaphragms. The conveying angle is 0-90 ° (the best angle is below 70 °), which is characterized by: horizontal inclined conveying can be completed in a narrow space with one equipment, and it has the advantages of high reliability of horizontal or small inclined conveying of general belt conveyor, energy saving, and reliable and economical lifting of materials with bucket elevator. This series of products are widely used in the departments of coal, grain, building materials, chemical industry, hydropower and metallurgy. They can transport various bulk materials with a bulk density of 0.5-2.5t/m3 within the ambient temperature range of - 19 ℃ -+40 ℃. For materials with special requirements, such as materials with high temperature resistance or with acid, alkali, oil substances, organic solvents and other components,

It must be proposed at the time of ordering that special rib conveyor belts of corresponding materials are used.

Product Details

1、 Overview

This series of products are mainly used for continuous conveying of bulk materials at large inclination angles, using conveyor belts with wavy edges and diaphragms. The conveying angle is 0-90 ° (the best angle is below 70 °), which is characterized by: horizontal inclined conveying can be completed in a narrow space with one equipment, and it has the advantages of high reliability of horizontal or small inclined conveying of general belt conveyor, energy saving, and reliable and economical lifting of materials with bucket elevator. This series of products are widely used in the departments of coal, grain, building materials, chemical industry, hydropower and metallurgy. They can transport various bulk materials with a bulk density of 0.5-2.5t/m3 within the ambient temperature range of - 19 ℃ -+40 ℃. For materials with special requirements, such as materials with high temperature resistance or with acid, alkali, oil substances, organic solvents and other components,

It must be proposed at the time of ordering that special rib conveyor belts of corresponding materials are used.

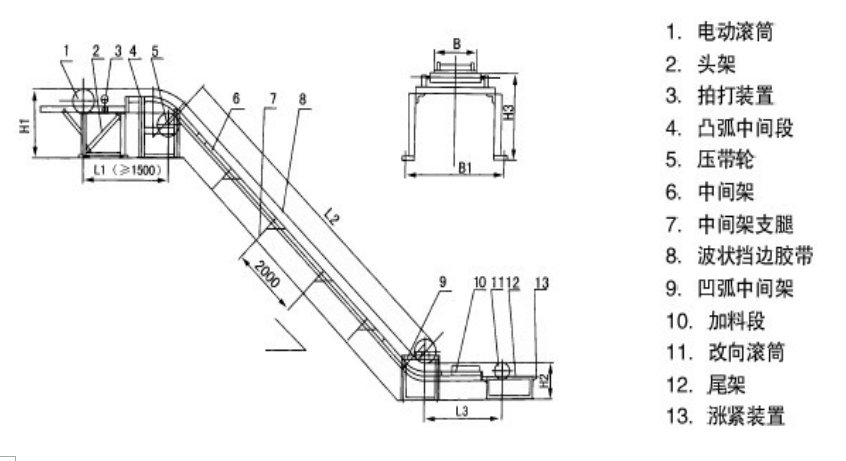

三、外形图:

4、 Model Selection

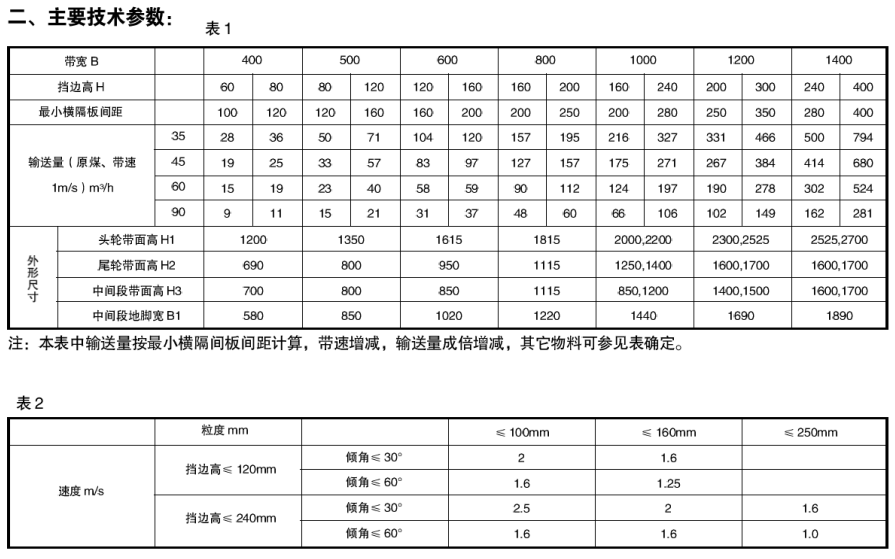

The belt width, rib height and belt speed of the conveyor shall be determined according to the characteristics, inclination angle and conveying volume of the conveyed materials and referring to Table 1 and Table 2. Including:

(1) The rib conveyor belt is divided into normal temperature (- 20~50 ℃), heat resistance (below 120C), high temperature resistance (below 180C), acid, alkali and oil resistance;

(2) When conveying large materials, the retaining edge should be higher; the belt width and retaining edge can also be not increased, and the conveying capacity can be increased by increasing the belt speed (1.25 m/s, 1.6 m/s, 2 m/s);

(3) The maximum conveying height is 70m, and the maximum particle size should be 30-40mm less than the height of the rib

(4) The distance between the upper bracket and the lower bracket is generally 1.2m, 2.4m when the inclination angle is greater than 60 °, 3-6m for the anti deflection bumper, 2200 for L3, and 1500 for the minimum

5、 Instructions

1. This table is only applicable to the preliminary simple type selection, and the final type selection results shall be determined according to the calculation results.

2. The data in this table are calculated based on the assumption that the linear speed of the tape V=1m/s, the spacing between diaphragms ts=0.25m, the material capacity y=1t/m3, and the lifting height H=10m. If the conditions are different, conversion should be appropriate.

3. Example of model selection:

It is known that the conveyed material is coal, the capacity is y=0.8t/m3, the particle size of material A is less than 40mm, and the conveying angle is β= 45 °, conveying capacity Q=85t/h, conveying height 15m, required bandwidth, belt speed and motor power. First, calculate that the conveying capacity of the belt conveyor should be 85t/h ÷ 0.5t/m3,=106.25m3/h, and then find that the conveying capacity of B=800 and H=160 is the closest to 96.6m3/h in the 45 ° inclination column of the table. Then change the linear speed to 1.25m/s, and the conveying capacity of the belt conveyor will be 96.6m3/h × 1.25=120.75m3/h, which can meet the use requirements. The corresponding required power is 4.59Kw × 15m÷10m × 1.25=8.6kw.

4. The type of diaphragm is selected according to the inclination of the conveyor.

18 °<3<40 ° T type, 40 °<B ≤ 60 ° C type, 60 °<p ≤ 90 ° TC type

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code