TD75 series belt conveyor

Belt conveyor

Product introduction: The belt conveyor is a kind of conveying equipment with large conveying capacity, low operating cost and wide application range. The conveyor belt is a traction component and a bearing component in the conveyor. Ordinary rubber conveyor belt is applicable to the working environment temperature of - 10~40 ℃. When the working environment temperature is lower than - 5 ℃, the vinylon core tape should not be used; When the working environment temperature is lower than - 15 ° C, ordinary cotton core tape should not be used; Under the working environment temperature lower than - 20 ℃, steel cord tape should not be used. The temperature of materials conveyed by ordinary rubber conveyor belt shall not exceed 80 ℃. When the temperature of materials conveyed is 80~150 ℃, heat-resistant belt shall be used. When conveying materials with high temperature of 300~500 ℃, heat-resistant belt can be used. When conveying acidic, alkaline, corrosive, oily materials and organic solvents, acid and alkali resistant, corrosion resistant and oil resistant rubber or plastic belts shall be used. The conveyor belt working in places with fire hazards shall be flame retardant.

Product Details

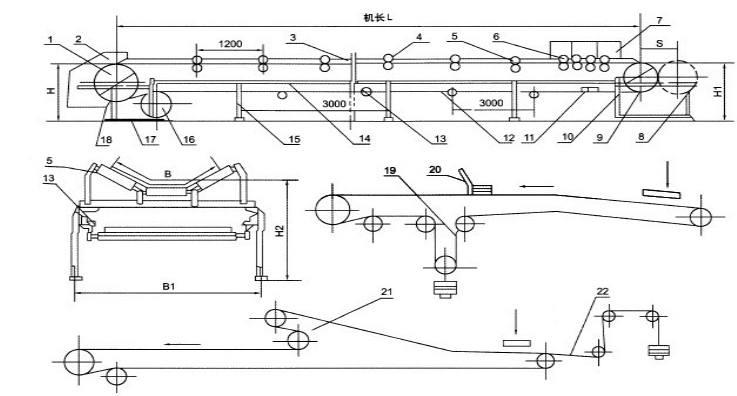

1、 Drive unit

When the power range is 2.2-5.5KW, it is easy to choose the electric roller as the drive, which can save space, but the ambient temperature is not easy to exceed 40 ℃

When the power is greater than 55KW, the motor shall be selected, and the reducer shall be driven separately from the drum. The surface of the transmission drum has three forms: bare steel surface, herringbone and diamond pattern rubber covering. The turning drum is divided into two types: smooth surface and glue surface.

The underpinning concrete is made of seamless steel pipes, with four types: groove type, parallel type, centering and buffering. Tensioning device: screw type tensioning device is applicable to shorter lengths (less than 100m), with three strokes of 500m, 8O0m and 100mm; The vertical weight tensioning device can automatically compensate the elongation of the conveyor belt by gravity as the tension changes; The heavy hammer truck type tensioning device is suitable for conveyors with long distance and large power. The tensioning stroke has three gears: 2, 3 and 4m. The fixed winch tensioning device is used for belt conveyors with long travel and large tensioning force (30-150KN). The maximum tensioning stroke can reach 16M

There are two kinds of sweepers: head sweeper and empty section sweeper.

Dischargers: manual plough dischargers and electric plough dischargers.

Electrical protection can be equipped with: conveyor belt deviation monitor; Belt slip monitor; Belt longitudinal tear signal monitor; Material level control monitor, etc.

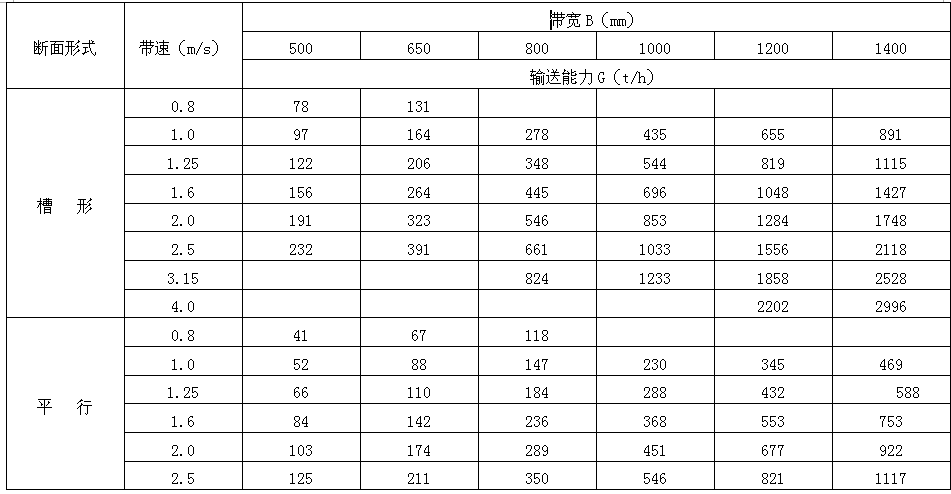

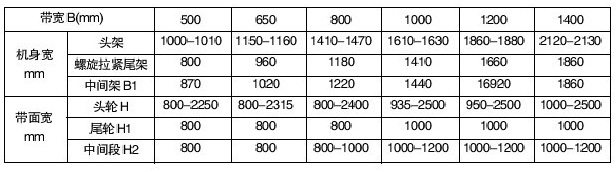

2、 Technical performance parameters

3、 Belt conveyor

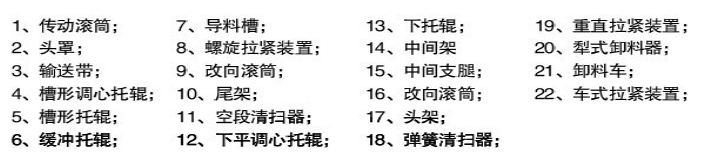

4、 Field use drawing

CN

CN

WeChat communication by scanning code

WeChat communication by scanning code